Provides accurate, versatile temperature regulation for standard AC heating devices like soldering irons. Starting with a ThermoCouple sensor that is attached to the tip of the iron, the TMPRmod uses true PID intellegence to change the AC power applied to the iron via Pulse Width Modulation.

TMPRmod is built around a pic16c72a, with an lcd display, AC zero-cross detection, max6675 TC interface and through 4 pin DIN socket, PID calculation, triac proportional PMW drive, and direct 110V AC to 5V DC power supply.

The following photos show how it is applied to a soldering iron to convert it from a normal non-temperature regulated unit into a high performance one. I am really enjoying my favorite setting of 196.4C, within +/-3C!

With it:

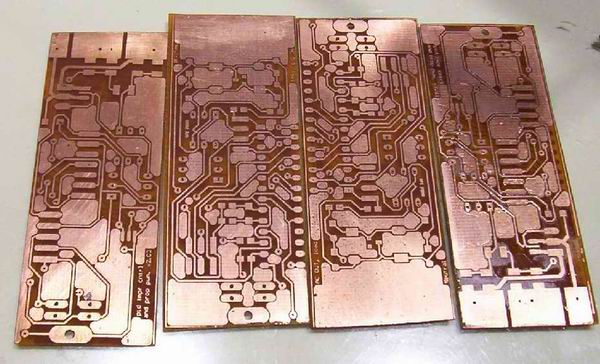

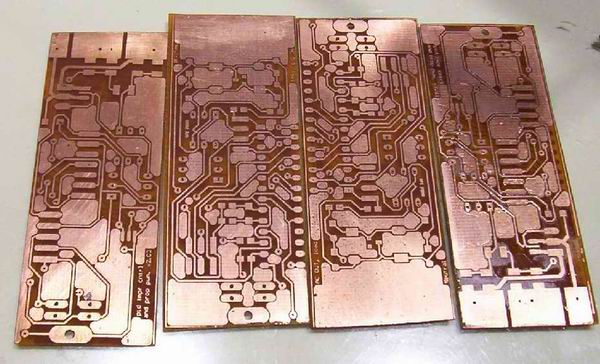

PCBs of 2nd version. It features AC power for PIC, and generates only 1.6W heat that need to be dissipated.

Case. LCD display is driven by HD44100. PCB is mainly SMT.

1st version at running, setting temperature is 196.4C, I use it daily. The 110V AC to 5V DC power supply generates more than 2W heat. I drilled holes in top and lower position to deal with it.

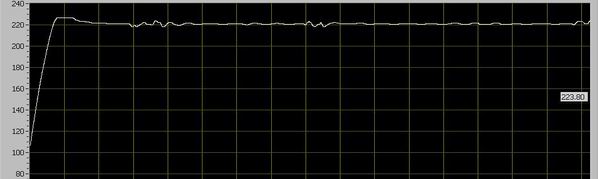

Recorded performance. X-time is 8000*200ms long. The temperature here is much higher than what I later found to be my favorite.

2nd version, generates only 1.6W and has better heat dissipation. The box does not even get warm any more. The "metal hole" at the top center, is an 100K SMT pot for temperature setting. This pot is read via ADC, and is now programmed for 0-300C. The button at top-right is for proportional pwm output of 110 AC with 0.5% accuracy over the 20-80% range.

Applied, within 30 minutes, to a photo laminator bought from Walmart. Accuracy even better than applied to solder iron and I guess due to little bit shorter dead time in PID. It brings astonishing quality improvement and is really essential in PCB toner transfer. I found temperature setting above 200C will result plastic deformation and smelling. Temperature below 160C, will obviously worsen protection during etching. Toner from different laser printers show different temperature responses. My PCB, like above, is setting at around 190C and printed out by Okidata led printer. I also tested different temperatures for doing photo lamination. It is very powerful tool after you put its temperature under control!

| Hoodia |

| file: /Techref/TMPRmod.htm, 5KB, , updated: 2005/5/30 10:45, local time: 2025/9/6 06:37,

owner: pML-yahoo-,

216.73.216.166,10-1-199-35:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://massmind.org/Techref/TMPRmod.htm"> TMPRmod </A> |

| Did you find what you needed? |

Welcome to massmind.org! |

|

The Backwoods Guide to Computer Lingo |

.