Ragged Chute Compressed Air Plant

Nature Produces Compressed Air

At Ragged Chute, 16 km southeast of Cobalt on the Montreal River, stands

the world's only water-powered compressed air plant.

Built in 1910, at the peak of the Cobalt silver boom, Ragged Chute Compressed

Air Plant transmits air-power to the local mining industry. Compressed air,

rather than electricity, is the main power source used by heavy mining equipment

such as drilling machines, grinders and hoists. Today, though, most mines

purchase electricity to run their own air compressors.

The late Charles H. Taylor

invented the hydraulic air compressor while living in Montreal. One spring

he observed the movement of the Ottawa River and, as water flowed over a

dam and under the ice, noticed that peculiar domes rose from the surface

of the ice. When they were pierced, compressed air escaped.

The late Charles H. Taylor

invented the hydraulic air compressor while living in Montreal. One spring

he observed the movement of the Ottawa River and, as water flowed over a

dam and under the ice, noticed that peculiar domes rose from the surface

of the ice. When they were pierced, compressed air escaped.

To Taylor's creative mind, the explanation was simple - when a mixture of

air and water is compressed, the air separates and rises. The air compresses,

and not the water, because the molecules in a liquid are already very close

together and, therefore, are almost impossible to compress.

Using this principle, Taylor determined that an efficient method to harness

hydraulic air-compression would be to drop the air-water mixture through

a shaft to an underground chamber. He designed the chamber in such a way

as to allow the water to flow through, and at the same time cause the air

to compress.

In the course of his experiments, Taylor discovered that the air pressure

and horsepower created could be increased or decreased by altering the length

and diameter of the intake shaft, and by changing the volume of water entering

the works.

Since it was built in 1910, Ragged Chute has practically run itself. While

under construction, in the early years of this century, a community of workers

did live on the site.

In 1945, Ontario Hydro purchased the Ragged Chute plant and continues to

supply local mines with the compressed air created there.

Only twice in its 70-year history has the plant been closed for major repairs

although, at one time, a dozen mines purchased thousands of cubic metres

of compressed air each month.

Today, the plants and the pipes that carry the air-power to the mines are

in need of a major overhaul. But the costs would be prohibitive. As a result,

the famous geyser-like blow-off from the plant is rarely seen except on weekends

when the local mines are shut

down.

How it works

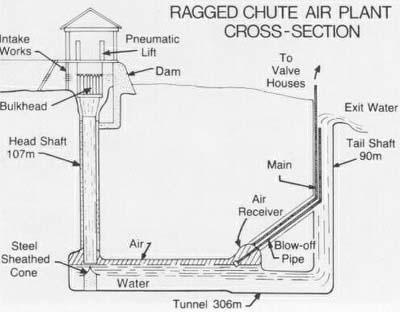

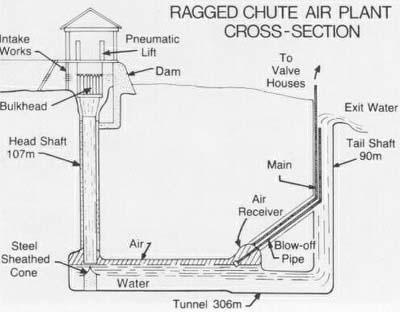

Ragged Chute was specifically designed to produce air compressed to 862.5

kPa (gauge). Its intake shaft is 107 m deep and the tunnel-chamber has a

blow-off valve to prevent increased pressure.

There are control gates to limit the amount of water entering the plant works.

As well, the two intake heads, each made up of 72, 36 cm pipes, can be raised

or lowered to maintain a constant depth over the bulkhead, usually about

46 cm of water.

From the heads, the water is fed into one pipe which widens just before the

bottom. This is designed to decrease the pressure in the pipe and allow the

air bubbles to collect and merge. At the base of the shaft are two steel-sheathed

concrete cones which break the initial impact of the air-water mixture, and

direct its flow into the horizontal chamber.

The chamber collects the compressed air and channels it to a receiver pipe,

61 cm in diameter. The receiver then carries the compressed air to a valve

house where it is transmitted to Cobalt for distribution.

The 51 cm diameter stell transmission pipe has telescopic expansion joints

every 0.8 km to allow for the effects of temperature change. The pipe is

above ground and can expand about a metre each 1.6 km on a hot, sunny day.

Compressed air must be dry because through friction, humidity decreases the

efficiency of both the pipeline and the motors using the air. Water vapor

also causes exhaust freezing in motors; the escaping air expands rapidly,

which requires a great deal of heat energy. And, finally, the moisture washes

away the lubricants within the motors.

The air transmitted from Ragged Chute is much drier than it was before

compression because the water temperature is so cold it condenses the moisture

in the air bubbles whil still in the intake shaft. The condensation then

remains with the water when the air-water mixture separates. The low humidity

of Ragged Chute air is one of the most remarkable features of the plant.

The blow-off

valve is a 30 cm pipe beside the receiver leading to a point underwater on

the river bed. It reaches into the tunnel-chamber to the critical depth where

it rests in water as long as the air is compressed to 862.5 kPa (gauge).

But when the pressure increases, the water level within the chamber lowers

slightly, allowing the excess pressure to escape. When it does blow, a stream

of water often shoots over 30 m into the air.

The blow-off

valve is a 30 cm pipe beside the receiver leading to a point underwater on

the river bed. It reaches into the tunnel-chamber to the critical depth where

it rests in water as long as the air is compressed to 862.5 kPa (gauge).

But when the pressure increases, the water level within the chamber lowers

slightly, allowing the excess pressure to escape. When it does blow, a stream

of water often shoots over 30 m into the air.

This spectacular, geyser-like blow-off is most commonly associated with the

Ragged Chute Compressed Air Plant.

file: /Techref/other/pump/raggedchute.htm, 5KB, , updated: 2004/11/5 19:54, local time: 2025/10/10 10:27,

216.73.216.137,10-3-124-149:LOG IN

|

| | ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions?

<A HREF="http://massmind.org/Techref/other/pump/raggedchute.htm"> Ragged Chute Compressed Air Plant</A> |

| Did you find what you needed?

|

.

The late Charles H. Taylor

invented the hydraulic air compressor while living in Montreal. One spring

he observed the movement of the Ottawa River and, as water flowed over a

dam and under the ice, noticed that peculiar domes rose from the surface

of the ice. When they were pierced, compressed air escaped.

The late Charles H. Taylor

invented the hydraulic air compressor while living in Montreal. One spring

he observed the movement of the Ottawa River and, as water flowed over a

dam and under the ice, noticed that peculiar domes rose from the surface

of the ice. When they were pierced, compressed air escaped.

The blow-off

valve is a 30 cm pipe beside the receiver leading to a point underwater on

the river bed. It reaches into the tunnel-chamber to the critical depth where

it rests in water as long as the air is compressed to 862.5 kPa (gauge).

But when the pressure increases, the water level within the chamber lowers

slightly, allowing the excess pressure to escape. When it does blow, a stream

of water often shoots over 30 m into the air.

The blow-off

valve is a 30 cm pipe beside the receiver leading to a point underwater on

the river bed. It reaches into the tunnel-chamber to the critical depth where

it rests in water as long as the air is compressed to 862.5 kPa (gauge).

But when the pressure increases, the water level within the chamber lowers

slightly, allowing the excess pressure to escape. When it does blow, a stream

of water often shoots over 30 m into the air.